TQC solve leaky test problem

Press Release - first

published in Hydraulics and Pneumatics Monthly (May 2004)

Faced

with a challenge from one of its customers to design a fully automated, very high

throughput leak testing system, Nottingham based manufacturer, TQC, enlisted the help of

automation specialist Festo to contribute handling and control expertise to the project.

TQC's customer contract required that the

company develop the system for 100% leak tests on welded metal T-pieces used in the water,

gas and construction industries. Although the unit cost of each T-piece component is very

low, absolute test confidence was paramount to the project as the cost of poor component

quality in the field is very high. |

|

|

Traditionally,

leak detection units have proved highly flexible, offering accurate measurement systems

for low to medium cycle rates. However, for TQC's customer, problems with this method were

envisaged when conducting leak tests on the large volumes and high throughput levels

demanded by the end-user application.

Conventional test units require a

stabilisation period within the measuring cycle before a reliable reading can be obtained.

The rapid pressurisation required by a high-throughput system causes the body of air

within the test piece to increase in temperature. In turn, this results in a pressure drop

(as defined by the General Gas Equation where P1V1/T1 = P2V2/T2

with V remaining constant in this instance). Therefore, if insufficient time is allowed

for the temperature to steady, the falling pressure gradient can potentially mask any true

leakage rate of the test piece. Of course, the need for a settling period directly

conflicts with the requirement for high throughput rates.

Mindful of this, the TQC development team

opted for the vacuum decay test methodology deployed in a leak detection system

manufactured by Swedish company Nolek. With the workspace volume in and around the T-piece

minimised through clever test chamber design, fast cycle rates could be achieved without

the danger of a pressure or temperature gradient. As the test piece is not subjected to

pressurised air, negligible temperature change occurs. Instead, the body of air at normal

atmospheric pressure within the T-piece is rapidly evacuated; the sensors can immediately

look for a rising pressure trend within the test piece. If detected, such an increase can

only result from air flowing back in to the T-piece through the welded joins - whereupon

the leaky part is rejected.

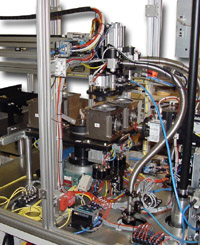

With the test philosophy defined, focus

shifted to the control and handling requirements of the test system. To match the

throughput of the chosen test process, fast flow rates were necessary for the handling

components. The Festo solution comprised several types of Festo guided and rodless

cylinders - all controlled by the company's acclaimed CPVT valve terminals. These not only

provide a compact installation but also high flow rates for fast movements and cycle

rates, allowing the handler to pick and present pairs of T-pieces to the leak test

chambers. They also permit flexibility of control - essential with more than sixty T-piece

variants and sizes from 12mm to 50mm - with interchangeable tooling facilitating fast

changeover between jobs. |

"We have specialised

in automated leak testing of components for many years," says Mark Jones, Technical

Sales Manager at TQC. "Our experience in production line test process automation

combined with the effective working partnership we have developed with Festo allowed us to

deliver a complete test system to our customer. Not only does it deploy the optimum test

techniques but it also achieves the extremely high throughput targets and delivers the

100% test confidence required to meet the customer's challenging productivity and quality

goals." |

|

"Like

TQC, Festo demonstrates a progressive approach to engineering and is prepared to invest in

forward-thinking developments. And along with TQC, Festo is a member of the 'Assembly Net'

organisation - a pan-European collaborative group whose stated agenda is to establish a

coordinated infrastructure to exchange the latest developments in Assembly System

Application and Design," explains Festo consultant Mark Grainger who worked with TQC

on the leak test project. Assembly Net seeks to provide a strategic vision on assembly

automation, integrating and supporting SMEs through conferences, newsletters and

workshops.

The DTI has recognised TQC's commitment

and awarded a Eureka grant of £850k over three years to assist in the development of an

interactive website that will allow engineers to design automatic assembly systems online. |

|

| This article was written by

Festo, for further information on their range of products, please visit the Festo website

at www.festo.com |

|

TQC Ltd, Hooton Street,

Carlton Road,

Nottingham, NG3 2NJ, United Kingdom

Tel: +44 (0)115 9503561

Fax: +44 (0)115 9484642

E-mail: sales@tqc.co.uk

|

|